Cartridge Heaters

- Swaged Cartridge Heaters

- Exceptional Heat Transfer Characteristics

- Welded end disc prevents contaminations

- Efficient Heat Transfer

- Optional Built-in Thermocouple

- Maximum 1400 ⁰F Operating Temperatures

- Various lead options

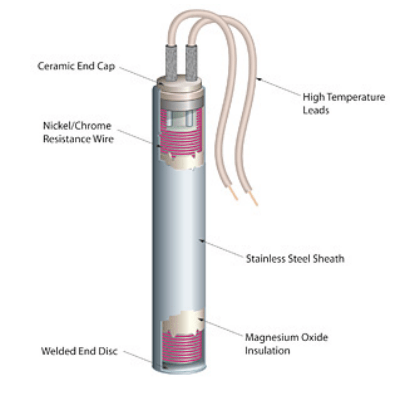

Construction

Nickel-chromium resistance wire is precisely wound on high purity magnesium oxide cores and filler materials swaged inside stainless steel sheath. Compacted design gives maximum heat transfer. Nickel-chromium resistance wire gives maximum heater life. High temperature lead wires or nickel pins are swaged into the heater. End discs are welded to prevent contamination.

Our cartridge heaters are meticulously designed and constructed to meet the demanding requirements of industrial heating applications. They consist of a stainless-steel sheath that offers excellent protection and durability. The heating element, usually made of high-resistance wire, is precisely wound and insulated to ensure efficient heat generation and transfer. The compact size and cylindrical shape of the cartridge heater allow for easy installation and integration into various equipment and systems.

Rapid Heat-Up and Precise Temperature Control: Cartridge heaters are renowned for their rapid heat-up times and precise temperature control capabilities. They can achieve high temperatures quickly, reducing downtime and improving operational efficiency. The design of our cartridge heaters ensures uniform heat distribution along the length of the heating element. This eliminates hotspots and provides consistent heating, resulting in improved product quality and production efficiency. Our cartridge heaters can withstand high temperatures, making them suitable for applications that require elevated heat levels. They deliver reliable and stable heat output, even in challenging environments. Energy Efficiency: Cartridge heaters are engineered for energy efficiency, minimizing heat loss and optimizing heat transfer to the target object or surface. This helps to reduce energy consumption and operational costs. We understand the diverse needs of our customers and offer a range of customization options for our cartridge heaters, including. Size and Power: Our cartridge heaters can be customized in terms of length, diameter, and power ratings to fit specific applications and provide optimal heating performance. Terminal Configurations: We provide various terminal options, such as screw terminals, stud terminals, or lead wires, to accommodate different installation requirements. Voltage and Wattage: Our cartridge heaters can be tailored to operate at different voltages and wattages, offering flexibility and compatibility with a variety of power.

As a leading manufacturer of cartridge heaters, we provide efficient and versatile heating solutions for a wide range of industrial applications. Our commitment to quality, performance, and customization options ensures that our customers receive tailored heating solutions that meet their specific requirements. With rapid heat-up, uniform heating, high temperature stability, and energy efficiency, our cartridge heaters offer exceptional performance and reliability. Count on us to deliver reliable and efficient heating solutions that enhance productivity and ensure consistent results across various industries

Specifications

- Diameter Tolerance: 0.002”

- Length Tolerance: 2%

- Wattage Tolerance: +5%, -10%

- Camber Tolerance: 0.025