Immersion Heaters

- Swaged for good Electrical Insulation

- High – Temperature Applications

- Rugged construction

- Long Life Metal Sheath

- Provide wiring box for electrical connection

- Multiple elements in one screw plug heater

- High, Medium or Low watt density for various processes

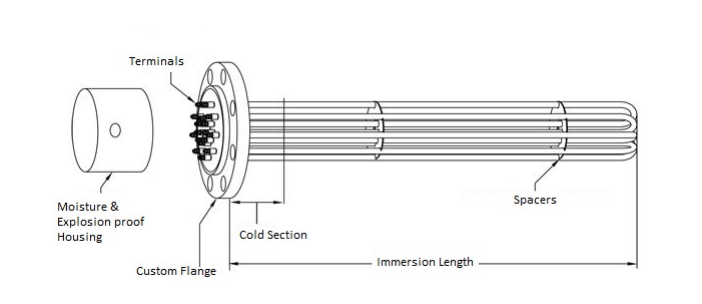

Screw Plug Heater

Screw Plug Immersion Heaters consist of tubular elements welded or brazed into a threaded screw plug

which can then be inserted into a threaded opening in a tank wall or through a mating full or half coupling.

The electric heating elements are constructed with high quality Nickel – Chrome resistance Wire, centered

in Stainless Steel Tube and insulated with high purity compacted MgO. The element tube material varies

according to specific requirements. The Elements are either welded or brazed to a threaded boss, which

is available in a variety of materials to suit the application.

Features

- Swaged for good Electrical Insulation

- High – Temperature Applications

- Brazed or Welded end construction

- Compact Design

- Rugged construction

- Long Life Metal Sheath

- Provide wiring box for electrical connection

- Multiple elements in one screw plug heater

- High, Medium or Low watt density for various processes

Application

- Hot Runner Mould System

- Ovens & Dryers

- Packaging Machinery

- Engineering Industries

- Plastic Processing Machinery

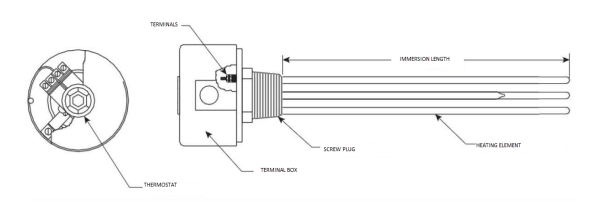

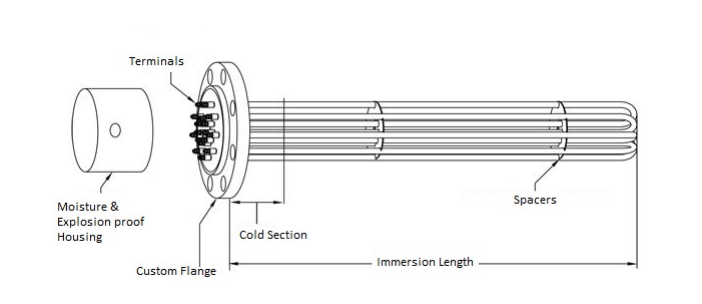

Flanged Heater

Flanged Immersion Heaters are manufactured with highly compacted tubular heaters which are bent U-Shape and welded or brazed onto a Flanges of various shapes and sizes. Flange heaters enable high

heating performance within the smallest space. They are commonly used in many chemical, petroleum

and water based applications.

Features

- Rugged Construction

- Swaged for good Electrical Insulation

- ASA Carbon Steel Flange ranges from 3” – 14”

- Moisture or explosion resistant terminal enclosure

- Thermowell for replaceable thermostat bulb

- Superior Chemical Resistance

Application

- Hot Runner Mould System

- Hot Water Storage Tank

- Warming Equipment

- Food Processing Equipment

- Boiler Equipment

- Freeze protection of any Fluid

Ceramic Infrared Heaters

Ceramic Infrared Heaters are efficient, robust heaters which provide long wave infrared radiation. They

are used in diverse range of industrial processes. Most plastics and many other materials absorbs

infrared wave best in this range.

Features

- Nickel – Chrome Resistance Wire

- Corrosion and Oxidation resistant

- Useful wavelength range (2-10 microns)

- Operating Temperature 550 ⁰F to 1400 ⁰F

- Average Operating Life up to 20,000 hours (depending on condition)

Application

- Thermoforming and Vacuum Forming

- Hot Stamping

- Heat Therapy