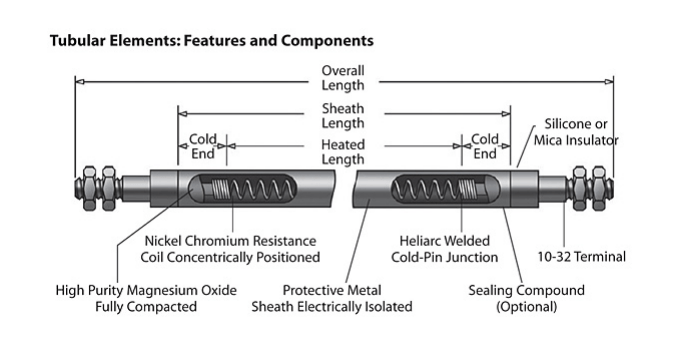

Tubular Heaters

- Swaged for good

- Electrical Insulation

- Uniform Thermal Heat

- Water Proof

- Low Maintenance

- Copper or Stainless Steel Terminals

Description

Tubular Heaters have the longest life span of any heater. A heating coil is inserted into a Stainless Steel Sheath, and MgO powder is used to fill the spaces between sheath and heating coil to create tubular shaped construction.

The heater is used in variety of applications due to its flexible shape, which is one of its major features. It is widely used in many fields to heat both gas and liquid.

Tubular element heaters have emerged as crucial components in industrial heating systems, providing efficient and reliable heat transfer for a wide range of applications. As a leading manufacturer, we take pride in producing high-quality tubular element heaters that excel in performance, durability, and versatility. In this document, we will explore the key features, benefits, and applications of our tubular element heaters, highlighting why they are the preferred choice for heating solutions across diverse industries.

Our tubular element heaters are meticulously designed and constructed to meet the demanding requirements of industrial heating applications. They consist of a durable metal sheath, typically made of stainless steel, that provides excellent protection against corrosion and mechanical damage. Inside the sheath, a specially designed heating element, typically made of high-resistance alloy wire, is precision wound to ensure optimal heat generation and transfer. The compact and robust design of tubular element heaters allows for easy installation and integration into various equipment and systems.

The design of our tubular element heaters promotes uniform heat distribution along the entire length of the heating element. This eliminates hotspots and provides consistent heating, resulting in improved product quality and production efficiency.

High Temperature Stability: Our tubular element heaters can withstand high temperatures, making them suitable for applications that require elevated heat levels. They deliver reliable and stable heat output, even in demanding environments.

Our heaters can be customized in terms of length, diameter, and power ratings to fit specific applications and provide optimal heating performance.

As a leading manufacturer of tubular element heaters, we offer powerful and versatile heating solutions for a wide range of industrial applications. Our commitment to quality, performance, and customization options ensures that our customers receive tailored heating solutions that meet their specific requirements. With rapid heat-up, uniform heating, high temperature stability, and energy efficiency, our tubular element heaters provide exceptional performance and reliability. Count on us to deliver reliable and efficient heating

Applications

- Water, Liquid and Air Heating

- Viscous Oil & Storage Tanks

- Vessels

- Chemical Industries

- Electroplating Industries